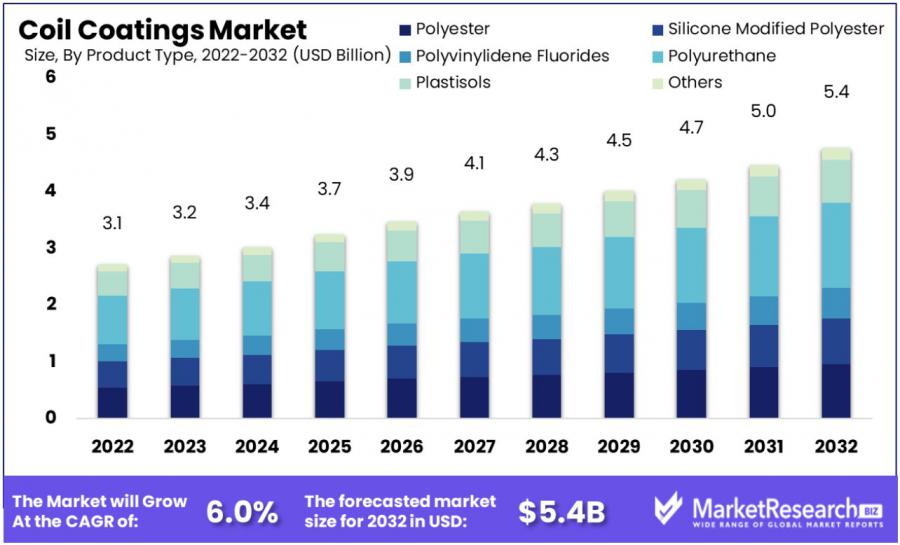

Coil Coatings Market Size and Share Forecast to Reach USD 5.4 Bn by 2032, Growing at a 6.0% CAGR

Coil Coatings Market size is expected to reach USD 5.4 Bn by 2032, growing from USD 3.1 Bn in 2022, at a CAGR of 6.0% during the forecast period.

NEW YORK, NY, UNITED STATES, January 22, 2025 /EINPresswire.com/ -- Report Overview

The Coil Coatings Market is projected to reach approximately USD 5.4 billion by 2032, up from USD 3.1 billion in 2022, expanding at a CAGR of 6.0% from 2023 to 2032.

Coil coatings refer to a type of protective finish applied to metal substrates, typically steel or aluminum, before they are formed into final products such as roofing materials, siding, and appliances. This method involves applying a layer of paint or coating to a metal coil that is then baked to create a durable, high-performance finish. Coil coatings offer a wide range of benefits, including corrosion resistance, improved aesthetics, and enhanced durability, making them a preferred choice across industries like construction, automotive, and consumer electronics.

The coil coatings market has seen significant growth in recent years, driven by the increasing demand for high-performance materials in both residential and commercial construction. The market is evolving with a shift toward more sustainable solutions, as environmental concerns and regulations push for the development of low-VOC (volatile organic compounds) and eco-friendly coatings. Additionally, the ongoing trend of urbanization and infrastructural development in emerging markets has spurred demand for advanced coatings that provide long-lasting protection against weathering, corrosion, and environmental degradation.

Key growth factors include rising construction activities, particularly in Asia-Pacific, and innovations in coating technologies that offer improved durability, energy efficiency, and aesthetic appeal. Additionally, the automotive industry is increasingly adopting coil coatings for lightweight and corrosion-resistant components. Opportunities within the market lie in the development of advanced coatings with multifunctional properties such as self-cleaning, anti-microbial, and heat-reflective features. These innovations are expected to drive further growth in both developed and emerging markets, creating new avenues for market players.

Get Instant Access to a Sample of Our Report and Uncover Valuable Market Insights at https://marketresearch.biz/report/coil-coatings-market/request-sample/

Key Takeaways

~~ The Coil Coatings Market is projected to grow from USD 3.1 Bn in 2022 to USD 5.4 Bn by 2032, at a CAGR of 6.0%, driven by high demand in construction, automotive, and appliance industries.

~~ Polyester-based coil coatings dominate the market, holding the largest share due to their performance, cost-effectiveness, and versatility across industries.

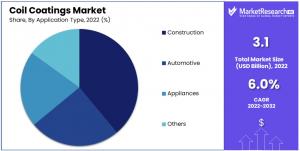

~~ The construction industry remains the largest consumer of coil coatings, with a significant share driven by the demand for weather-resistant and aesthetically appealing building materials.

~~ Asia Pacific leads the global coil coatings market with a dominant 55% share, driven by industrialization and urbanization, particularly in China and India.

~~ Polyester-based coil coatings lead the product type segment, supported by their widespread application in construction and automotive industries.

Regional Analysis

Asia Pacific Coil Coatings Market with Largest Market Share of 55% in 2023

Asia Pacific leads the global coil coatings market with a 55% share in 2023, driven by rapid industrial growth, urbanization, and strong demand from the construction and automotive sectors. Countries like China, India, and Japan are key contributors, with growing demand for coil-coated products in architecture and automotive applications.

North America and Europe also show steady growth, driven by demand for sustainable, energy-efficient materials. The Middle East & Africa are expanding due to infrastructure development, while Latin America is experiencing moderate growth, fueled by economic recovery and increasing construction activities. Asia Pacific’s dominance remains strong, supported by its industrial expansion and diverse sector demand

Market Segmentation

By Product Type Analysis

Polyester-based coil coatings dominate the product type segment due to their balance of performance, cost-effectiveness, and versatility, especially in construction and automotive sectors. SMP coatings are valued for superior weatherability, PVDF coatings for excellent chemical resistance and durability in harsh environments, and Polyurethane Adhesives coatings for their superior finish and abrasion resistance. Each product type caters to specific performance needs, driving market diversity.

By Application Type Analysis

The coil coatings market is primarily driven by the construction industry, which demands durable, weather-resistant, and aesthetically pleasing materials for exterior building applications like roofing and wall panels. In the automotive and appliance sectors, coil coatings provide protection and aesthetic enhancement. Polyester coatings dominate due to their balance of performance and cost. The market is expanding with emerging applications in automotive, appliances, and other industries like furniture and industrial equipment, highlighting the versatility of coil coatings.

Order the Comprehensive Report Now and Enjoy a 30% Discount at https://marketresearch.biz/purchase-report/?report_id=2317

Key Market Segments

By Product Type

~~ Polyester

~~ Silicone Modified Polyester (SMP)

~~ Polyvinylidene Fluorides (PVDF)

~~ Polyurethane (PU)

~~ Plastisols

~~ Others

By Application Type

~~ Construction

~~ Automotive

~~ Appliances

~~ Others

Emerging Trends:

~~ Sustainable and Eco-friendly Products: There is a growing demand for eco-friendly coil coatings made from water-based or low-VOC (Volatile Organic Compounds) formulations. Manufacturers are focusing on creating coatings that reduce environmental impact and comply with stricter environmental regulations.

~~ Customization and Innovation in Coatings: Coating manufacturers are increasingly offering customizable solutions to meet specific customer needs, such as specialized coatings for durability, appearance, and weather resistance. Innovation is leading to the development of coatings with enhanced performance, including self-healing properties.

~~ Adoption of Advanced Technologies: The use of advanced technologies like nanocoatings and 3D coatings is on the rise. These innovations offer higher resistance to corrosion, UV damage, and scratching, making them ideal for applications in various industries including automotive and construction.

Top Use Cases:

~~ Automotive Industry: Coil coatings are widely used in automotive manufacturing, particularly in car bodies, where the coatings provide both aesthetic appeal and corrosion resistance.

~~ Building and Construction: Coil coatings are extensively used in roofing materials, facades, and structural components of buildings due to their durability and weather-resistant properties.

~~ Appliance Manufacturing: Coil coatings are applied in the production of household appliances like refrigerators and air conditioners to improve the longevity and appearance of metal surfaces.

Major Challenges:

~~ Price Volatility of Raw Materials: The price fluctuations of raw materials such as titanium dioxide and resins can affect the cost and supply chain stability of coil coatings.

~~ Environmental Regulations: Increasing environmental regulations related to the use of hazardous chemicals in coatings and disposal of waste materials pose challenges for manufacturers in the coil coating industry.

~~ Limited Durability of Certain Coatings: Despite innovations, some coil coatings still face challenges in terms of longevity, particularly when exposed to harsh weather conditions or extreme temperatures.

Top Opportunities:

~~ Growth in Green Construction: The rise in sustainable construction practices presents an opportunity for coil coating manufacturers to expand their offerings of eco-friendly and energy-efficient coatings.

~~ Technological Advancements in Coatings: The development of advanced coatings with enhanced properties such as self-healing, anti-microbial, or anti-graffiti coatings opens up new applications in various sectors, including public infrastructure and high-end construction projects.

~~ Expansion in Emerging Markets: Rapid urbanization and industrialization in emerging economies, particularly in Asia-Pacific and Latin America, are creating a high demand for coil coatings, particularly for use in construction and automotive sectors.

Key Players Analysis

In 2024, the global coil coatings market remains highly competitive, driven by key players such as AkzoNobel N.V., BASF SE, and PPG Industries Inc. These leaders are actively innovating to enhance product offerings and address growing demand for sustainable and high-performance coatings. AkzoNobel and BASF are expanding their portfolio to include environmentally friendly, energy-efficient products, capitalizing on the rising regulatory focus on eco-conscious materials. Beckers Group, Henkel AG & Co. KGaA, and Kansai Paint Co. Ltd. are also strengthening their position through strategic partnerships and geographic expansions, catering to diverse sectors, including construction and automotive. Nippon Paint Holdings Co. Ltd. and The Sherwin-Williams Company are leveraging advanced technologies, such as digital solutions and automation, to improve coating application efficiency. Meanwhile, Axalta Coating Systems and Dura Coat Products Inc. are focused on innovation in corrosion-resistant and durable coatings. Together, these companies are shaping the market landscape, intensifying competition and driving growth across multiple regions.

Explore Custom Research Solutions Before You Buy the Report

Top Key Players in the Coil Coatings Market

~~ AkzoNobel N.V.

~~ BASF SE

~~ Beckers Group

~~ Henkel AG & Co. KGaA

~~ Kansai Paint Co., Ltd.

~~ Nippon Paint Holdings Co., Ltd.

~~ PPG Industries Inc.

~~ The Sherwin-Williams Company

~~ The Valspar Corporation

~~ Axalta Coating Systems

~~ Dura Coat Products, Inc.

~~ KCC Corporation

~~ The Chemours Company

~~ Wacker Chemie AG

~~ The Dow Chemical Company

~~ Goldin Metals Inc.

~~ Nucor Corporation

~~ BDM Coil Coaters LLC

Conclusion

The global coil coatings market is projected to grow from USD 3.1 billion in 2022 to USD 5.4 billion by 2032, at a CAGR of 6.0%, driven by rising demand across the construction, automotive, and appliance sectors. Key trends include a shift towards sustainable, low-VOC coatings, innovations such as self-healing and anti-microbial technologies, and expanding use in emerging applications. Asia Pacific dominates the market, with rapid industrialization and urbanization in countries like China and India fueling demand. Challenges such as raw material price volatility and stringent environmental regulations remain, but the growing emphasis on eco-friendly solutions and technological advancements present significant opportunities for market expansion. Leading players like AkzoNobel, BASF, and PPG Industries continue to innovate and expand, ensuring a competitive and evolving market landscape

Lawrence John

Prudour

+91 91308 55334

email us here

Visit us on social media:

Facebook

LinkedIn

Distribution channels: Manufacturing

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release