Laser Cladding Materials Market is Estimated to Witness High Growth Owing to Increasing Application in Aerospace.

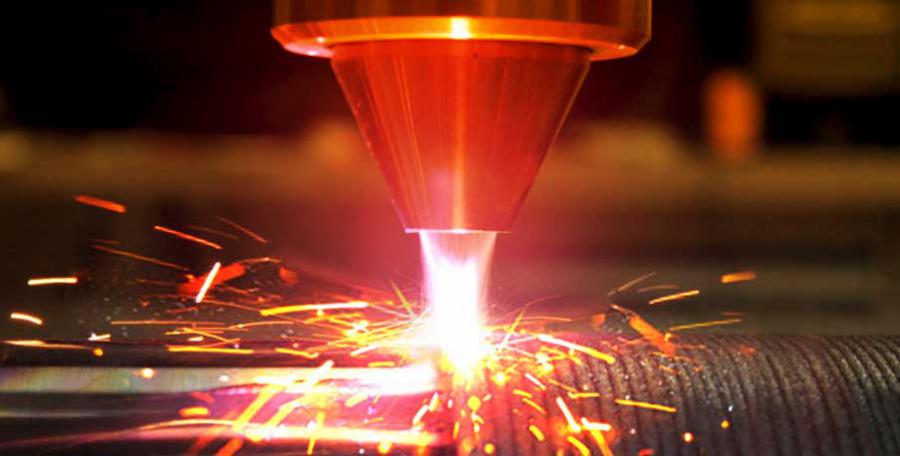

Laser cladding is a surface engineering technique which is widely performed in industries to enhance the surface properties of the metallic equipment.

BURLINGAME, CALIFORNIA, UNITED STATES, May 21, 2024 /EINPresswire.com/ -- Market Overview:

Laser cladding materials are coatings deposited onto metal substrates to enhance surface properties. These materials are used to repair worn components and protect from wear, corrosion and heat in applications across automotive, oil & gas, aerospace, mining and other industries.

Market Dynamics:

The laser cladding materials market is driven by increasing demand from the aerospace industry. The aerospace industry is expecting high growth in the coming years due to rising air passenger traffic worldwide. Laser cladding is widely used in the aerospace industry to repair worn engine components and protect critical parts from extreme heat and wear. It helps increase the lifespan of components and reduce maintenance cost. Furthermore, stringent government regulations regarding fuel efficiency and emission standards in the automotive industry have increased the adoption of laser cladding to enhance performance of engine parts. Growing applications across various industries are expected to support growth of the laser cladding materials market during the forecast period.

Increased Demand for High-Performance Materials to Withstand Harsh Environments

The global laser cladding materials market is being driven by the increasing demand for high-performance materials that can withstand harsh environmental conditions from industries such as automotive, aerospace, and energy. Laser cladding allows manufacturers to apply wear and corrosion resistant coatings to components, enabling them to perform efficiently even in demanding applications involving high temperatures, pressures, and abrasion. This capability to improve the lifespan and performance of parts through functional grading is contributing significantly to the growth of the market. Metals and alloys with excellent hardness, strength, and resistance to thermal shock are finding increasing usage in laser cladding for critical engine and turbine components. To ensureoptimized productivity and reduced downtime, companies across industries are actively utilizing laser cladding technologies.

Get a Sample Copy of the Report : https://www.coherentmarketinsights.com/insight/request-sample/3482

Key Players Covered In This Report:

FST, AMC Powders, Oerlikon Metco, Hoganas AB, Praxair S.T. Technology, Hongbo Laser, Henan Igood, Wall Colmonoy, DURUM, Sentes-BIR, and Shandong Sitaili

Market Segmentation:

By alloy type

Nickel-based

Cobalt-based

Iron-based

Carbide & carbide blends

Others

By end user Industry

Power Generation

Automotive

Oil & Gas

Aviation

Mining

Construction

Others

Key Region/Countries are Classified as Follows:

The following section of the report offers valuable insights into different regions and the key players operating within each of them. To assess the growth of a specific region or country, economic, social, environmental, technological, and political factors have been carefully considered.

The section also provides readers with revenue and sales data for each region and country, gathered through comprehensive research. This information is intended to assist readers in determining the potential value of an investment in a particular region.

◘ North America (United States, Canada, and Mexico)

◘ Europe (Germany, France, UK, Russia, and Italy)

◘ Asia-Pacific (China, Japan, Korea, India, and Southeast Asia)

◘ Latin America (Brazil, Argentina, Colombia, etc.)

◘ The Middle East and Africa (Saudi Arabia, UAE, Egypt, Nigeria, and South Africa)

Buy this premium report: https://www.coherentmarketinsights.com/insight/buy-now/3482

Rising Adoption of Additive Manufacturing Techniques

Another major factor providing a push to the laser cladding materials market is the rising adoption of additive manufacturing techniques globally. Laser cladding is an additive repair method that allows for fast and cost-effective restoration of worn or damaged components. Producing custom 3D parts with desired surface properties layer by layer eliminates the need for expensive replacement. The benefits of laser cladding such as near-net-shape fabrication, reduced material wastage, and design flexibility are encouraging more manufacturers to incorporate 3D printingand additive repair in their production workflows. The growing relevance of Industry 4.0 is also driving increased R&D towards laser-based additive techniques like cladding for mass customization applications.

Stringent Environmental Regulations Limiting Use of Hazardous Materials

Stringent environmental regulations across regions pose a restrain on the laser cladding materials market. Certain chemicals used in the formulation of laser cladding powders may contain toxic elements like chromium, cadmium, lead, etc. Regulatory bodies are increasingly putting restrictions on the application of coatings with hazardous materials, especially in the automotive and aerospace sectors. This is compelling powder manufacturers to explore alternatives to hazardous alloys and develop compositions compliant with restrictive legislations. However, it is difficult to replicate the unique properties delivered by restricted compositions, which can adversely impact the performance capabilities of laser cladding in certain applications. High research costs for developing substitute materials is also a challenge.

Opportunity for Developing Bio-Based and Recyclable Laser Cladding Materials

The growing environmental consciousness and sustainability drive presents new opportunities for the laser cladding materials market. Powder producers are investigating the potential of bio-based feedstocks like agricultural waste to manufacture eco-friendly cladding compositions. Efforts are also ongoing to develop methodologies to recycle waste cladding powders or coated scraps containing precious metals. Recyclable laser cladding materials will help reduce industrial waste and carbon footprint. The market opportunity exists in tapping the untapped biomass resources to deliver sustainable alternatives meeting performance needs. Strategic collaboration between industries, academia and governments can support research into novel cladding materials manufactured from renewable resources with closed-loop recycling capabilities.

Increasing Demand from the Medical Industry

A key trend gaining momentum in the laser cladding materials market is the increasing use of these materials in medical applications such as 3D printed implants. Researchers are exploring the possibilities of using laser cladding to apply thin layers of biofunctional coatings onto metallic implants to enhance biocompatibility. Coatings containing elements like hydroxyapatite, TiO2, etc. improve integration of implants with tissues. Laser cladding is also studied for repairing worn out implants to avoid replacement. Medical device manufacturers are continuously demanding materials capable of delivering exacting surface properties required for the human body. Going forward, the need for non-toxic, highly biocompatible laser cladding materials tailored for customized medical devices will continue to open up new opportunities.

Request For Customization at: https://www.coherentmarketinsights.com/insight/request-customization/3482

The report answers a number of crucial questions, including:

➥ Which companies dominate the global Laser Cladding Materials Market ?

➥ What current trends will influence the market over the next few years?

➥ What are the market’s opportunities, obstacles, and driving forces?

➥ What predictions for the future can help with strategic decision-making?

➥ What advantages does market research offer businesses?

➥ Which particular market segments should industry players focus on in order to take advantage of the most recent technical advancements?

➥ What is the anticipated growth rate for the market economy globally?

Mr. Shah

Coherent Market Insights Pvt. Ltd.

+1 206-701-6702

email us here

Visit us on social media:

Facebook

Twitter

LinkedIn

EIN Presswire does not exercise editorial control over third-party content provided, uploaded, published, or distributed by users of EIN Presswire. We are a distributor, not a publisher, of 3rd party content. Such content may contain the views, opinions, statements, offers, and other material of the respective users, suppliers, participants, or authors.